Click here to view my auctions on EBAY

|

|

|

|

Buffum Tool Company

Founded by Frank W. Buffum

The company made mechanic tools, blacksmith tools, household tools, yard tools, engineer tools and bayonets made for World War I.

The trademark of the swastika was used. Before World War II. The trademark was a primitive religious ornament or symbol originally in the form of a gammadion, but variously modified, the most typical being a Greek Cross with the ends of the arms germ at right angles, and prolonged to the length of the up right arms, clock wise, or counter clockwise. It dates back to the bronze age in Europe and still exist as a religious symbol in India, Persia, China, Japan and among North, Central and South American Indians: Beleived to be a token of good luck or blessing.

The business approximate date was early 1900's until Buffum died in 1922 when it was then put into estate where it sold to a group of five men from St. Louis, Mo. where it stayed in business until 1940.

Names used

BUFFUM TOOL COMPANY

BUFFUM TOOLS, INC.

RELIABLE TOOL AND SPECIALTY COMPANY

|

|  |

|

|

|

| The H. Channon Copany Building |

|

| Corner of Randolph Street and Wacker Drive |

| Channon ad for a Bedrock jointer for $8.00 |

|

| ad for Bailey #1 smooth for $3.80 |

|

H. Channon Company Founded 1875 Wholesale Distributors of Supplies and Equipment, Tools, and Machinery for all Industries.

Seven stories and basement--172,000 square feet of floor space. two blocks from the Loop, The elevated railway, the Northwestern Station.

123-149 North Wacker Drive, Chicago, Illinois

| Speed in Handling |

|

| Packing Room |

Check out this mail room, "Your order is copied in ditto. A copy is whisked to each Warehouse floor through pneumatic Tubes. Order Fillers pick up the required items, place them in the gravity chute. No waiting for elevators."

Arriving in the Packing Room, each item is inspected, checked, packed, addressed and delivered to the Shipping Room, then to the fleet of Channon trucks at the private loading platform. Five trucks can load simultaneously.

| Corridor of the main office |

|

| Exterior or Will Call and Merchandise department |

|

|  |

|

|

|

| J.E. Haseltine 1880 |

|

| Portland, Oregon |

| 1956 Hasteline 115,000 sq. ft. office & warehouse |

|

| soon to be erected on the 7 1/2 acre tract by our Steel warehouse in Guilds Lake |

| 1946 Haseltine 510 First Ave. South |

|

| Senaca, Washington |

| 1956 Haseltine ad |

|

| Starrett calipers |

|

This is an introduction in a 1956 catalog by William A haseltine:

Portland counted just 1,200 inhabitants and Oregon had three years to wait before becoming a state when the Northrup family set up the business that was to become J. E. Haseltine & Co. It was 1856 this was the horse's heyday, and Northrup catered to the carriagemaker, farrier and blacksmith. Large stocks of horseshoes, saddles, and wagon wood stock were carried.

Gradually the business grew and evolved. Several moves to larger quarters in the Front Street area of Portland were made, and additional lines were added. Setbacks were experienced too: severe damge was sustained in the disastrous fire of 1873 and in the Great Flood of 1894.

In 1883, J.E. Haseltine journeyed from Portland, Maine to Portland, Oregon and joined E. J. NOrthrup. Upon Mr. Northrup's death the same year, Mr Haseltine purchased the the stock of the company and renamed it J. E. Haseltine & Co. The eight employees at that time have grown to 180.

As industry has mushroomed, we have kept pace. The automobile replaced the horse, and we put in large stocks of automotive supplies. Later, as Northwest industry expanded and diversified, we began stocking the many tools and supplies for industry which are cataloged here. To serve many of oru customers in Washington and Idaho, we opened a branch in Seattle in 1932 and in Spokane in 1946. and in 1950, our present steel warehouse was erected. Pioneers in establishing an industrial supply business in Portland, we have also been pioneers in selling new techniques, such as welding, and new products, such as heat-treated cap screws and automatic and semi-automatic welding machines. You, our customers are the ones responsibel for our growth and our success. We thank you for your support and look forward to serving you during our "Second Century of Service."

| 1938 General office & sales rooms 115 S.W. Second |

|

| iron steel and and pipe warehouse Northrup street |

|

|  |

|

|

|

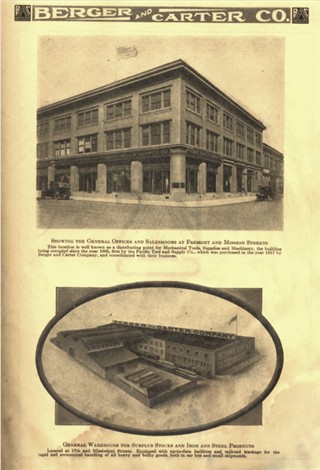

| General offices & salesrooms Fremont & Mission St |

|

| General warehouse for surplus stocks and iron and steel products |

|

Berger and Carter company established 1902 General supplies for manufacturing and public service corporations machine and automotive repair shops. Jobbers and distributors 400 to 410 Misssion Street, at Fremont, San Francisco, California. This location is well known as a distributing point for mechanical tools, supplies and machinery, the building being occupied since the year 1906, first by the Pacific Tool and Supply Co, which was purchased in the year 1917 by Berger and Carter Company, and consolidated with their business. The General warehouse was located at 17th and Mississippi Streets. Equipped with up-to-date facilities and railroad trackage for the rapid and ecomomical handling of all heavy and bulky goods, both in car lots and small shipments.Information from a #23 catalog 1923.

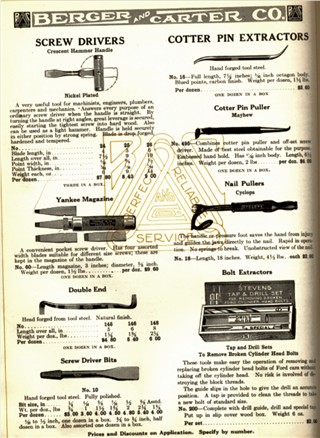

| Berger ad for screw drivers cotter pin extractors |

|

| nail pullers |

|

|  |

|

|

|

|

|

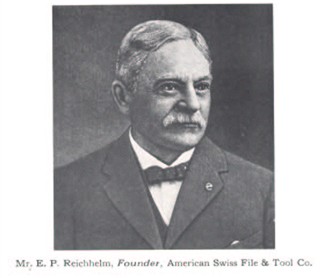

Edward P. Reichhelm founded the American Swiss File & Tool Company in 1900. Up to that time, American manufacturers had tried in vain to equal the high quality of the precision files, which were imported from Switzerland.

Mr. E.P. Reichhelm was particularly well qualified to solve this problem. Following his early training as a machinists apprentice, which interrupted by five years of service in the Civil War, he had developed and manufactured for many years various types of implements for work requiring precision tools.

Recognizing the importance of uniformity in heat treatment of the steel for such tools, Mr. Reichhelm originated the modern gas furnace for industrial purposes and organized the American Gas Furnace Co. to develop this type of furnace commercially. By the time he conceived the idea of manufacturing precision files, Mr. Reichhelm was therefore able to bring to this challenging task a unique experience in each of the essential manufacturing processes of making fine tools.

The Swiss pattern file business started by Mr. Reichhelm was a success from the start, due to the skill with which his American Swiss pattern files were made, and to the care and conscientiousness that he insisted upon during each step in their manufacture.

These standards have been faithfully continued throughout the more than 40-year progress of the company under the direction of both Mr. E. P. Reichhelm and his son, Paul F. Reichhelm, who has conducted the business for the last 25 years.

This information from a 1941 Swiss File catalog.

|

|  |

|

|

|

|

|

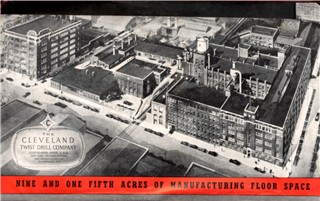

Cleveland Twist Drill - Manufacturers of drills, reamers, screw extractors arbors, mandrels, Sockets, mills, Counter bores, Carbide tipped tools, Mo-Max, ground tool Bits, And cut off blades high speed tools. The main factory was Located in Cleveland Ohio and established in 1876 incorporated in 1904. This information was obtained from the number 45 1947 catalog. They also had offices in New York, Detroit, Chicago, Dallas, Los Angeles, San Francisco and London.

Union Twist Drill - Located in Athol, Massachusetts, on the Boston and Maine Railroad, Fitchburg division, comprises 153,607 square feet devoted exclusively to the Production of cutters and drills. The buildings are as follows: Building number one, 137ft. long, 62ft. wide, three stories.

Number one ext. 112 feet long, 37ft. wide.

Building number two, 300ft. long, 95 feet wide.

This building contains the hardening and annealing Plant.

The most advanced ideas enter into its equipment, And exceptional Facilities enable us to produce uniformly the highest grade of work.

Building number three, 118ft. long, 62ft. wide, three stories.

Number Three ext. 141ft. long, 62ft. wide, Four Stories.

Building number nine, 113ft. long 62 feet wide, Three stories.

Powerhouse, 64ft. long and 62ft. wide. This information was found in the April 29, 1918 union twist drill catalog

|

|  |

|

|

|

| |

When 20-year-old Danish blacksmith Vilhelm Petersen sailed into Boston Harbor, little did he know that his journey would lead to the establishment of American Tool Companies, Inc. In 1902, "Bill" Petersen settled in Minden, Nebraska, where he worked for a fellow Danish blacksmith, keeping horses shod, plow shares sharpened and wagons repaired.

Bill Petersen was an inventor at heart. With the introduction of the automobile and farm tractor, blacksmithing was on the decline. During the long Nebraska winters, Petersen experimented with his ideas. In 1921, he invented and patented a unique wrench with a "vise-like" grip.

By 1924, Petersen had refined his invention by adding a locking lever. He patented the enhanced tool and gave it an innovative name that would become world famous:

VISE-GRIP� locking pliers. He registered the distinctive clasped hands logo, a symbol that today represents the most recognized hand tool brand in the world.

American Tool Companies, Inc., led by Allen Petersen, the founders grandson, has evolved into a leading global manufacturer and marketer of hand tools, cutting tools and power tool accessories. The company has more than 4,400 employees and manufacturing facilities throughout North America, Europe, Brazil, and the Pacific Rim.

Today, its product lines include VISE-GRIP� locking pliers, clamps and wrenches, IRWIN� wood boring and cutting tools, QUICK-GRIP� clamping products, RECORD� hand tools, MARPLES� woodworking tools, JORAN� drill bits, JACK hand saws, POWERPRESS pipe clamps, TURBOMAX� drill bits, PROSNIP snips, MARATHON� and SPRINT� saw blades, UNIBIT� step drills, HANSON� taps, dies and drills, CHESCO hex tools, SPEEDBOR2000� wood boring bits, and STRAIT-LINE marking tools. 1924 Bill Petersen granted basic patent for locking pliers

1934 Petersen Manufacturing Co. formed to manufacture and market VISE-GRIP� locking tools

1938 First official VISE-GRIP� tools plant opens in an old DeWitt drug store with a staff of 37

1957 Modern-design 10WR� VISE-GRIP� locking pliers goes on market with curved jaw and wire cutter

1962 The Cumberland, Wisconsin plant opens, manufacturing twist drills

1979 Gorham, Maine plant opens, manufacturing HANSON� and IRWIN� tools

1985 American Tool Companies, Inc. was formed and accquired Petersen Manufacturing Co.

1993 American Tool Companies acquires The Irwin Company, a revered manufacturer of power tool accessories and cutting tools.

1994 American Tool Companies acquire Joran Bor A/S, a leading manufacturer of masonry drill bits

for the building and construction markets worldwide

1995 American Tool Companies acquire Hans Schr�der A/S, the world's largest producer of hand saws, in Asn�s Denmark

American Tool Company site |

|  |

|

|

|

| |

Goodell-Pratt Company Was founded in 1888 and incorporated 1895 At Greenfield, Massachusetts. Many lines of tools were obtained through a series of acquisitions including: Richardson and sons Wells brothers. In 1931 Millers falls Company, also of Greenfield Massachusetts acquired the company.

Ohio tool company was founded in Columbus, Ohio in 1823, and for 40 years used prison labor supplied and by contract from the state penitentiary. Then the late 1880s Ohio tool company employed civilian workers and in 1891 purchased the Auburn tool company. The company ceased operations in 1920.

|

|  |

|

|

|

| |

|

|

|

|

|

|

|

|

|

Alexander Vaughan

|

|

|

|

|

|

|

The company that is today Vaughan & Bushnell Mfg. Co., was founded in Peoria, Illinois by Alexander Vaughan. It began as a plumbing business, which in those days consisted of digging wells and piping water into the kitchens of the local citizenry. Alexanders business prospered, but the inventive, 18-year old blacksmith had his eye on bigger things.

|

|

|

|

|

|

The split-rail fencing of farmland was beginning to be replaced by steel posts and wire. Alexander had an idea for improving the design of the augers used for digging post holes. He turned idea into reality, and believing that Chicago would outstrip Peoria as a business center, moved to the Windy City. He set up a blacksmith shop in a room behind a hardware store owned by Sidney Bushnell.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

On June 15, 1869, Alexander was granted U.S. Patent No. 91,387 for his Improved Post Auger. Customer satisfaction with Vaughan post augers led to requests for other hand tools, and Alexander soon found himself in the custom tool business. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

There were several Vaughan salesmen traveling the Mississippi and Missouri River valleys selling augers and other tools when tragedy struck in the form of the Great Chicago Fire of 1871. The fire destroyed the fledgling Vaughan Company. In its aftermath the strained finances of the company forced Alexander to seek additional capital. Sidney Bushnell offered to furnish the needed funds. The company was incorporated in 1882 as the Vaughan & Bushnell Mfg. Co. |

|

|

|

|

|

Sanford S. Vaughan

|

|

By this time Vaughans product line had grown to include quite a variety of tools and implements. One of the first Vaughan hammers, a so-called killing hammer, was in great demand for delivering the coup de grace to cattle being processed at the Chicago Union Stock Yards. Besides hammers, tool such as those needed for blacksmithing and shoemaking were also being manufactured, together with chisels, punches, pincers, nippers, star drills, planes, wrecking bars and pliers. |

|

|

|

|

|

|

|

| Sanford S. Vaughan, Alexander's only son, joined the company in 1886, just before a move to larger facilities.As time passed, obsolete items were dropped from the line. More hammers, and a variety of hatchets and axes, were added. The great demand for hammers, hatchets, axes and wrecking bars soon made them the primary items in the line. Vaughan eventually came to specialize in the manufacture of hammers and other striking tools. After Alexanders death in 1905, Sanford took over full management of the company. He was an innovator and made many basic changes in the design of the traditional carpenters hammer, changes which are to be found in all hammers being made today. Handle-to-head wedging was improved, and Vaughan patented the triple-wedge design. In 1918 Vaughan introduced its classic 999 pattern ripping hammer. Sanford served the company for 65 years until his death in 1951. |

Sanfords son, Howard Sr., joined the company in 1922, the year the interests of the Bushnell family were purchased by the Vaughan family. He was named President and Chief Executive Officer in 1945. One of his major concerns was that demand for toolsboth those carrying the Vaughan label and those of the many private label brands which Vaughan was by then supplyingwould soon outstrip |

|

Howard A Vaughan, Sr. |

the capacity of the Chicago plant. A chance meeting at a trade show with a garden tool manufacturer headquartered in Bushnell, Illinois, led to Vaughan's move there in 1940. Limited manufacturing commenced in Bushnell in the fall of 1940, and was gradually expanded during World War II. The towns location and ample labor supply proved so favorable that, in 1950, it was decided to consolidate all manufacturing operations in Bushnell.

| | |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Howard A Vaughan, Jr.

|

|

|

|

|

|

|

|

|

Howard A. Vaughan, Jr. joined the company in 1956, was named Vice President of Sales in 1960 and became President in 1966. Vaughan during that time was a major supplier of striking tools, both under its own name and many other proprietary brands, as well. Taking as his goal a substantial increase in sales of Vaughan-labeled tools, Howard Jr. first ordered a major modernization of Vaughans manufacturing processes to ensure that adequate production capacity would be available to absorb a market expansion. |

|

|

|

|

|

|

|

|

|

|

Vaughans insistence on consistently high quality was recognized when, in 1993, the company became the first striking tool manufacturer in the world to be awarded the International Standards Organization ISO 9002 Certification.In 1963 the administrative headquarters of the company were established in Hebron, Illinois. A subsidiary, The V&B Mfg. Co., was formed in 1966, and a plant built for the manufacture of hickory handles. Located in Walnut Ridge, Arkansas, V&B Mfg. ensured availability of top quality handles. In 1992, GroundBreakers� landscaping tools were added to the product line. Innovative in design and construction, they quickly found wide acceptance among landscapers, contractors and home gardeners. Vaughan in 1994 acquired a sawmill in Centerville, Tennessee. This facility, situated in the heart of a hickory forest, guarantees Vaughan a virtually unlimited supply of the highest quality hickory for both striking tools and GroundBreakers landscaping tools. |

|

|

|

Todays Vaughan & Bushnell is of a size and sophistication that Alexander Vaughan could scarcely have imagined. While new manufacturing techniques and processes have played a part, the people of Vaughan are the true foundation of the companys success. Dedicated to the goal of producing the finest striking tools in the world, they have helped transform Vaughan from a small maker of hand tools to the worlds largest manufacturer of striking tools. Vaughan tools are made with an attention to detail that is exceptional. Four generations of the Vaughan family and the dedicated craftsmen who produce their products care a great deal about the tools that carry the Vaughan name, and the care is obvious. | |

Vaughan & Bushnell

|

|  |

|

|