|

| This picture courtesy of RITOOLMAKERS |

History Firsts

| 1851 |

The Vernier Caliper |

| 1855 |

Precision Gear Cutting & Dividing Engine |

| 1861 |

The Universal Milling Machine |

| 1861 |

The Formed Tooth Gear Cutter |

| 1868 |

Micrometer Caliper |

| 1876 |

The Universal Grinding Machine |

| 1880 |

The Automatic Screw Machine |

| 1920 |

Measuring Microscope (Leitz) |

| 1944 |

The Electronic Gage |

| 1963 |

Coordinate Measuring Machine (DEA) |

| 1974 |

DCC Coordinate Measuring Machine (Leitz) |

| 1976 |

The Digital Vernier Caliper |

| 1978 |

CMM with Full 3-D Scanning Probe (Leitz) |

| 1981 |

Shop Floor Measuring Robot (DEA) |

| 1985 |

Open Architecture Measuring Software (Leitz) |

| 1987 |

Icon-Based Measuring Software |

| 1988 |

Metrology Grant Program (Assistance to over 100 Colleges, Universities, Schools) |

| 1993 |

WINDOWS technology in Measuring Software (DEA) |

| 1993 |

B&S ISO 9001 Certification |

| 1994 |

Leitz ISO 9001 Certification |

| 1995 |

DEA ISO 9001 Certification |

|

A Measure of Perfection

The History Of

Brown & Sharpe

As Told By

Henry Dexter Sharpe

Excerpts From An Address To the

Newcomen Society of England

Riverside, Rhode Island

May 4, 1949

New Page 1

D avid

Brown, born in Warren, Rhode Island, carried on a store for the disposal of

clocks and watches, together with silverware, and as times became very poor he

took "to the road" as a peddler to dispose of his stock through New England

villages. As time went on, he established himself in Pawtucket, in the making of

clocks of various sorts, in which occupation, for a time, his son joined him.

Joseph R. Brown, the son, learned his machinery trade in the shops of

Walcott & Harris in Pawtucket. On attaining his majority in 1831, we find Joseph

setting up a little shop of his own for the manufacture of small tools for

machinists and for the building of lathes. Mutual interest proved such, however,

that father and son soon combined their activities, starting a partnership in

1833, located at 60 South Main Street in Providence, under the firm name of

David Brown & Son, for the making and repairing of clocks and watches and doing

other light mechanical work of precision.

This work was carried forward upon a modest scale, as indicated by the fact

that their shop was without power or a forge. David Brown had such a high

reputation in the city for making and repairing clocks that without doubt he had

ample patronage. As was his son, David was a pronounced character. He was known

as a skeptic, which presumably means he was not affiliated with any religious

body. As an explanation of his willingness to repair the clock of the Old

Baptist Meeting House he is reported to have replied: "One has always to give

the devil his due." Many church clocks in New England were made by him and his

son. A number have endured to the present. Among his clocks, is a treasured one

in the Brown & Sharpe Works, having a compensating mercury-filled pendulum. It

still is an excellent timepiece, after a hundred years of continuous service.

David Brown

This embryo industry was the nucleus from which has evolved the business of the Brown & Sharpe Mfg. Co., making the Year 1833 notable. The mechanical business of the New England territory, in 1833, principally was concerned with making cotton machinery. The evolution growing out of the manufacture of clocks and instruments of one kind or another was in itself of importance.

Though both of the Browns had shared in the impress of the cotton machinery industry, their interest in mechanical things largely was centered in articles calling for greater precision.

It would seem that from the beginning of his business life Joseph R. Brown was a forward-looking, self-respecting man. Like many a new enterprise, the young firm suffered a serious loss through a fire which occurred in 1837; and, as frequently happens, the loss was but slightly covered by insurance. Nevertheless, the partners were not discouraged, and they went into temporary quarters while the building was being re-erected. Two years later, additional space was secured in a neighboring building. The partnership, however, was terminated a few years later, following the advent of the "Dorr War." David went West in disgust, and settled in Illinois; while the son continued his retail and jobbing business.

In 1848, the business was removed to 115 South Main Street in Providence; and two years later, in 1850, we find Mr. Brown starting out along new lines. His pioneer work was directed towards raising the standard of accuracy in machine shop operations, because in that year, he built an Automatic Linear Dividing Engine, so fundamentally correct in its design and of such careful workmanship that today, after 100 years of continuous service, it, and other machines of like design built during the following years, have not been superseded for their particular class of work.

To build these machines for graduating rules of steel led not only to the manufacture of high-grade steel, ivory, and boxwood rules in great varieties with standard and special graduations, but also to the development and marketing of the Pocket Vernier Caliper, of which it has been said: "It was the first practical tool for exact measurement which could be sold in any country at a price within the reach of the ordinary machinist, and its importance in the attainment of accuracy for fine work can hardly be overestimated."

Mr. Brown says, regarding the graduating machine: "having been convinced by long experience that it is impractical to make a screw sufficiently accurate to be used in a dividing engine, I have constructed a machine on an entirely new principle which I am happy to say produces the most satisfactory results."

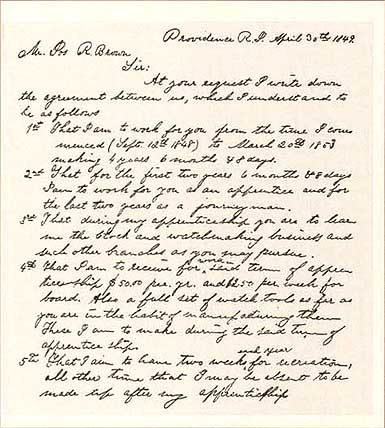

We see, in imagination, the picture of a little shop with its show-window filled with watches, clocks, scientific instruments, and mechanics' tools, carefully and neatly arranged by Lucian Sharpe, the apprentice, who had commenced work for Mr. Brown on September 12, 1848. Mr. Brown's old job book, of the period, entering jobs for oiling and repairing clocks and watches, has sandwiched in between such items the momentous entry: "Lucian Sharpe came to work for me this day as apprentice."

Lucian's apprenticeship was of the old type of indenture, payments for services of $50.00 per year being made by his father, Wilkes Sharpe; there being in addition an allowance of $2.50 per week for board, except for such times as he boarded in Mr. Brown's home.

As a youth at school he acquired habits of promptness, industry, and integrity; and he had a fondness for reading, a retentive memory, and unusual bodily vigor. From his beginning with Mr. Brown, he showed a commercial talent and administrative ability of high order and real promise. As a youth at school he acquired habits of promptness, industry, and integrity; and he had a fondness for reading, a retentive memory, and unusual bodily vigor. From his beginning with Mr. Brown, he showed a commercial talent and administrative ability of high order and real promise.

As he completed a grammar school course and attended two years at Providence High School, he went to work for the Providence Machine Company, where a few months experience failed to enlist his enthusiasm. Through the counsel of his friend and mentor, Owen Mason, who was highly regarded in the city during those years, he applied for opportunity of apprenticeship with Mr. Brown. It is said that Mr. Mason said of Mr. Brown's shop that he had noticed "though the shop was small, it was always busy." From testimony of associates of these years the apprentice showed certain qualities which made him stand out from the other employees; he was the first at the shop in the morning, and when the workmen arrived he had opened the safe and arranged the show-window; swept out the shop, and had everything in readiness.

Early in his apprenticeship we find him writing letters for Mr. Brown, even writing the letters, when required, in good French, in corresponding with French agents in New York City through whom watch parts and books were imported. He is reported to have translated one or more French books into English for his own use and that of his shop mates.

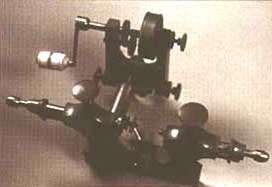

Watchmaking instrument made by Lucian Sharpe as part of his apprenticeship agreement.

As a part of the agreement of apprenticeship, Lucian Sharpe was privileged to provide himself with a set of tools such as were then used by watchmakers. A watchmaker's lathe made by him during these years of apprenticeship still exists. On March 1st, 1853, before the expiration of his contract with Mr. Brown, he was made a full partner in the enterprise newly created under the name of J. R. Brown & Sharpe. With no funds to undertake a financial participation, this was furnished, it is understood, by his old friend, Mr. Owen Mason, his mentor of years previous, notably in his coming as an apprentice with Mr. Brown himself.

This partnership proved an effective combination: Mr. Brown, with his mechanical ability, and Mr. Sharpe, as a business executive. Mr. Brown thoroughly disliked office and business duties, preferring to spend his whole day in mechanical problems which came to his notice; whereas Mr. Sharpe thoroughly enjoyed the business activities so important to a young enterprise. In spite of their varying abilities, perhaps because of them, these men had throughout life a warm personal regard and sincere respect each for the other. They were more than congenial in many ways, and each helped and influenced the other, through their mutual confidence. From the date of this partnership, the business prospered and expanded. This partnership proved an effective combination: Mr. Brown, with his mechanical ability, and Mr. Sharpe, as a business executive. Mr. Brown thoroughly disliked office and business duties, preferring to spend his whole day in mechanical problems which came to his notice; whereas Mr. Sharpe thoroughly enjoyed the business activities so important to a young enterprise. In spite of their varying abilities, perhaps because of them, these men had throughout life a warm personal regard and sincere respect each for the other. They were more than congenial in many ways, and each helped and influenced the other, through their mutual confidence. From the date of this partnership, the business prospered and expanded.

Under the name of J. R. Brown & Sharpe they first occupied a space of 60 x 30 feet, and employed 14 workmen.

We learn that at this time a cask of Stubs' wire, tools, etc. was imported by the firm from England, the customs charges of $600 straining its modest financial resources.

While in the early days Mr. Brown did a regular business in the repairing of watches, he made only two complete watches - one for his wife and one for himself. He did, however, make a regular line of watchman's clocks, the manufacture of which was continued long after the jobbing and repair business in timepieces was abandoned.

Hand-operated watchmaking instrument.

Meanwhile, they continued to make certain textile manufacturing appliances, the manufacture of some of which endured for many years, and one even to this day - the well known yarn reel.

An important step in developing the business after the formation of the partnership was the building of a Precision Gear Cutting and Dividing Engine by Mr. Brown, in 1855. An accurate method for making gears was being sought by him based upon the studies of Professor Willis, then in commanding attention. A machine for this purpose required accuracy in a dividing wheel, from which teeth could be produced on the wheel itself. On this dividing wheel provision was made for graduating on a copper ring set in the wheel, this being centered by original methods devised by Mr. Brown. The graduating itself was done in the City of Washington under his personal direction, at the Coast and Geodetic Survey, upon a machine whose master wheel came from the famous Troughton & Simms concern in London, then apparently the last word in such work. The machine was a notable achievement leading to the building of other similar machines and to an expanding business in gear cutting, circular graduating, and index drilling, thus giving an increasingly wider reputation for high grade work.

|